Environment

As a global agrochemical company, we strive to minimize our environmental impact while supporting farmers' efforts to increase global food production in a more sustainable way. We take a comprehensive approach to monitoring our environmental impact and mitigating risks at every stage of our product life cycle, starting from raw material supplies, to production, transportation, application, and all the way to end-of-life management. This approach enables us to continuously improve our environmental performance indicators.

Our environmental sustainability policy was designed based on listening and learning from farmers, employees, surrounding communities, environmental organizations, and other stakeholders. This is how we become familiar with their expectations from us, and with innovative technologies and ways that can help us better manage in the field.

We actively work to engage the communities living near our operation sites, to jointly create projects that reduce potential disturbances. In our production plants, we host regular community dialogues to listen to and address public concerns.

For example, we send a biannual operational update to community leaders, as well as run a verified monitoring station that transmits real-time information about chemical emissions, so our stakeholders can be certain that we are well below admissible levels.

HSE Management

To put our commitment into practice, we have established and continuously maintain an effective environmental management system for most of our production processes, based on the International Standard ISO 14001.

Our Health, Safety and Environment (HSE) Policy adopts a sustainable approach to protecting both our People’s health and safety, and the environment, by promoting renewable energy, recycling, and emissions reduction. We strongly maintain our commitment to the nearby communities, and foster a corporate culture of individual responsibility at all our sites.

ADAMA has updated its HSE and Sustainability Policy to include aspects of process safety, which are associated with environmental incidents such as spills and release. Moreover, ADAMA formulated four new environmental and sustainability procedures covering two-way impact, quantification methods, and short- and long-term activities to meet its global and local sustainability goals. The procedures focus on the following topics:

- Carbon footprint

- Water resources use

- Hazardous materials and waste

- Reporting and transparency

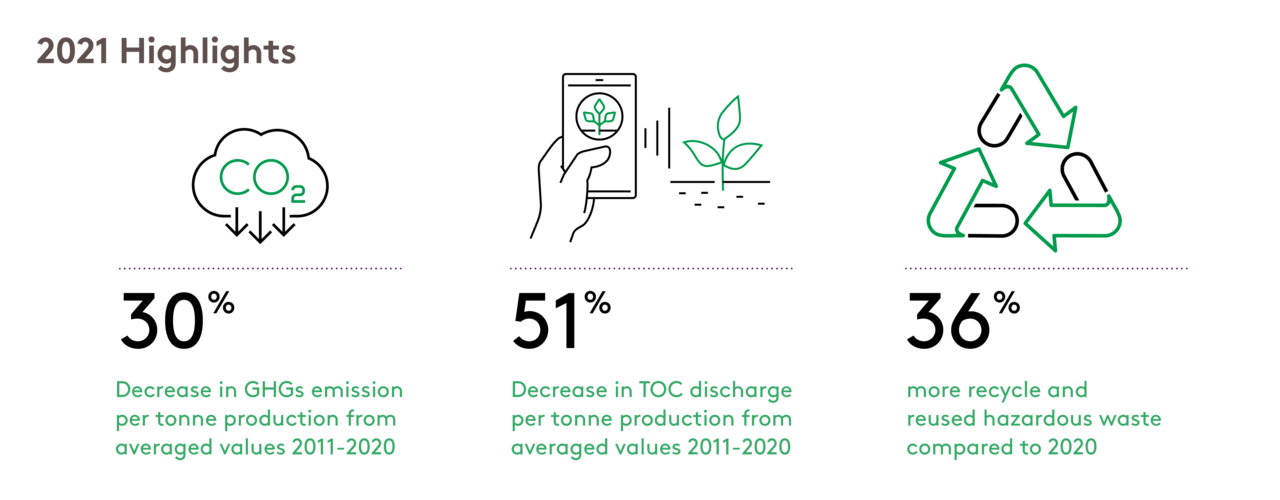

Making Environmental Progress

Beyond Compliance

Despite our growing production volumes, we are committed to outperforming regulatory requirements and dramatically limiting our energy, water, and hazardous waste footprint. We have launched a variety of projects that will steadily improve our environmental performance in absolute terms over the coming years.

"At ADAMA, we make sure that the HSE field is managed methodically and systematically to ensure significant achievements over time and as part of our commitment to sustainability, which is embedded in our core business. Our publicly published reports and ESG ratings reflect our progress, and we are proud of it."

Eran Segal

Head of HSE and Operational Sustainability

Investing in a Greener Future

In 2021, we increased our investment in preventing and mitigating environmental risks while reducing the potential environmental effects of our activities. Specifically, we constructed a new chlorine gas production facility, shifting from technology based on mercury to a membrane-based technology. Moreover, we built a new 5000m3 wastewater reactor and 1000m3 balancing pool to enhance treatment efficiency and redundancy. We installed two new scrubbers to upgrade our air emission control measures. Our facilities are managed according to stringent European directives or analogous local regulations.

| 2019 | 2020 | 2021 | |

|---|---|---|---|

| Investment in facilities (million USD) | 9 | 19 | 60* |

| Current costs (million USD) | 48 | 51 | 54 |

*Including China ( 19 million USD )

Sustainable Operations

- We operate five (5) major synthesis sites and twelve (12) formulation and packing sites.

- In 2021, the new Chinese subsidiary, Jiangsu Huifeng Bio Agriculture Co., Ltd, started to report on its environmental and sustainability performance.

- Whenever significant changes or new operations are planned, we first carry out a survey to identify potential environmental risks.

- We strive to improve our production processes by integrating advanced technological and environmental solutions at all our sites.

Meeting ADAMA's emissions goals and continuing our journey to become a more sustainable company compels us to apply the best available technologies.

The following technologies were adopted by ADAMA to realize our environment and sustainability vision:

| Pillars | Technological and organizational solutions |

|---|---|

| Water and wastewater |

|

| Energy use |

|

| Air pollutants and odor nuisance |

|

| Hazardous waste |

|

| Noise nuisance |

|

| Accident prevention |

|

Looking Ahead

Sustainability Assessments

ADAMA is continuously improving its sustainability performance in leading global and local ESG ratings. EcoVadis and Maala (Israeli sustainability ranking organization) ratings focus on environment, labor and human rights, ethics, and sustainable procurement.

CDP (Carbon Disclosure Project) focuses on climate change impact, disclosure practices, targets, policies, and governance.

EcoVadis ranked ADAMA for 2020 data at “Bronze” level and Maala as “Platinum+”.

The 2021 assessment is ongoing for both initiatives, and final scores will be available towards Q3 2022. CDP ranked ADAMA as D, typical for first year companies, starting their climate change journey.

We used these ESG ratings to analyze the results, formulate a detailed gap analysis and prepare a multiyear plan.

Learning and Improving

Since 2022, ADAMA HSE and sustainability newsletters have provided global information on new regulations, major HSE incidents, and sustainability activities of agrochemical companies.

The goal is to expose our HSE teams to upcoming regulations, implement corrective actions from external HSE incidents, and to learn about sustainability activities within our industry.

We treat all accidents with the highest care, and invest in training and a culture of safety, so that even though we cannot guarantee a zero-incident rate, we can learn from mistakes to prevent future occurrences.

In 2020, we experienced four major incidents, which were immediately contained and treated.

Case Study

Odor Nuisance at Makhteshim Production Site, Neot Hovav Israel (2021)

Poor control of PCMM (Perchloromethyl mercaptan) emissions from a production facility caused an odor nuisance at the site and neighboring communities. We identified the root cause of the emissions and replaced a bag filter system to sharply decrease emissions and odors.

Overflow of Effluents from a Storage Tank at Makhteshim Production Site, Beer Sheva, Israel (2021)

We stopped effluent flow in the pipe, pumped excess effluents to a tanker back to the wastewater treatment plant, identified the breakdown point, and fixed the broken pipe within a few hours. An electrical check to detect leaks along the pipeline was embedded into routine maintenance to prevent future issues.